Disclaimer: I do not recommend using Cosmic Indifference on functional ware. It may leach heavy metals and should not be applied to food surfaces.

Galactic Indifference is a really pretty glaze. It shimmers in the light. It crystallizes when thick. I have not seen a glaze like it - it has quite the unique chemistry - yet it is as much trouble as it is desirable. Although claimed to work from cones 6 to 10, in typical firings it is a disappointing mass of over crystallization. The glaze is at its full glory in soda firing, but even then, uneven soda distribution can make pieces hit or miss.

I think it's possible to have all of Galactic Indifference's best aspects at cone 6. And I think I can make the glaze even better by fixing issues with the cone 10 soda version.

Galactic Indifference on Glazy

NC-4 is a soda feldspar and FF 3124 is a boron frit.

How does Galactic Indifference work? Looking at the recipe, most of the ingredients are found in other typical cone 10 glazes, but there are two things that jump out: the use of lithium carbonate and 12% titanium oxide.

Lithium carbonate is an uncommon glaze ingredient. It is a powerful flux and also crystallizes in runny glazes. Both of these properties are being used in Galactic Indifference. Lithium melts at cone 6 too, so it can be easily added.

What sets Galactic Indifference apart from other glazes is its inclusion of a whopping 12% titanium oxide. Titanium is hard to dissolve in glazes and just 2% can start to create crystals. Galactic Indifference (plus extra sodium from soda firing) contains an absurd amount of flux just to do one thing: dissolve all the titanium.

For my cone 6 version, I'll use boron as my main power flux. I'll increase boron as much as I can while keeping these key aspects of Galactic Indifference the same:

For the initial test, I use glaze calculation software to come up with two formula that meet specific requirements. I think that these properties are important to how the glaze functions:

To start, I performed a linear blend between two recipes. One recipe melts too much and the other one melts way too much (theoretically). I expect some blend of the two to dissolve the titanium without being overly runny.

| Aggressive Melt | Lax Melt | |

|---|---|---|

| Lithium Carbonate | 4 | 4 |

| Whiting | 20 | 20 |

| Nepheline Syenite | 18 | |

| Ferro Frit 3134 | 24 | 20 |

| Ferro Frit 3195 | 20 | |

| Silica | 6 | |

| Tile 6 Kaolin | 20 | 20 |

| Titanium Dioxide | 12 | 12 |

When mixing this glaze, I noticed that it had a very thick consistency. Adding water didn't help and caused the glaze to crack when drying. Water should be kept low and the glaze should be flocculated with something like sodium silicate.

| 100-0 Mix | 67-33 Mix | 50-50 Mix | 33-67 Mix | 0-100 Mix |

|---|---|---|---|---|

|

|

|

|

|

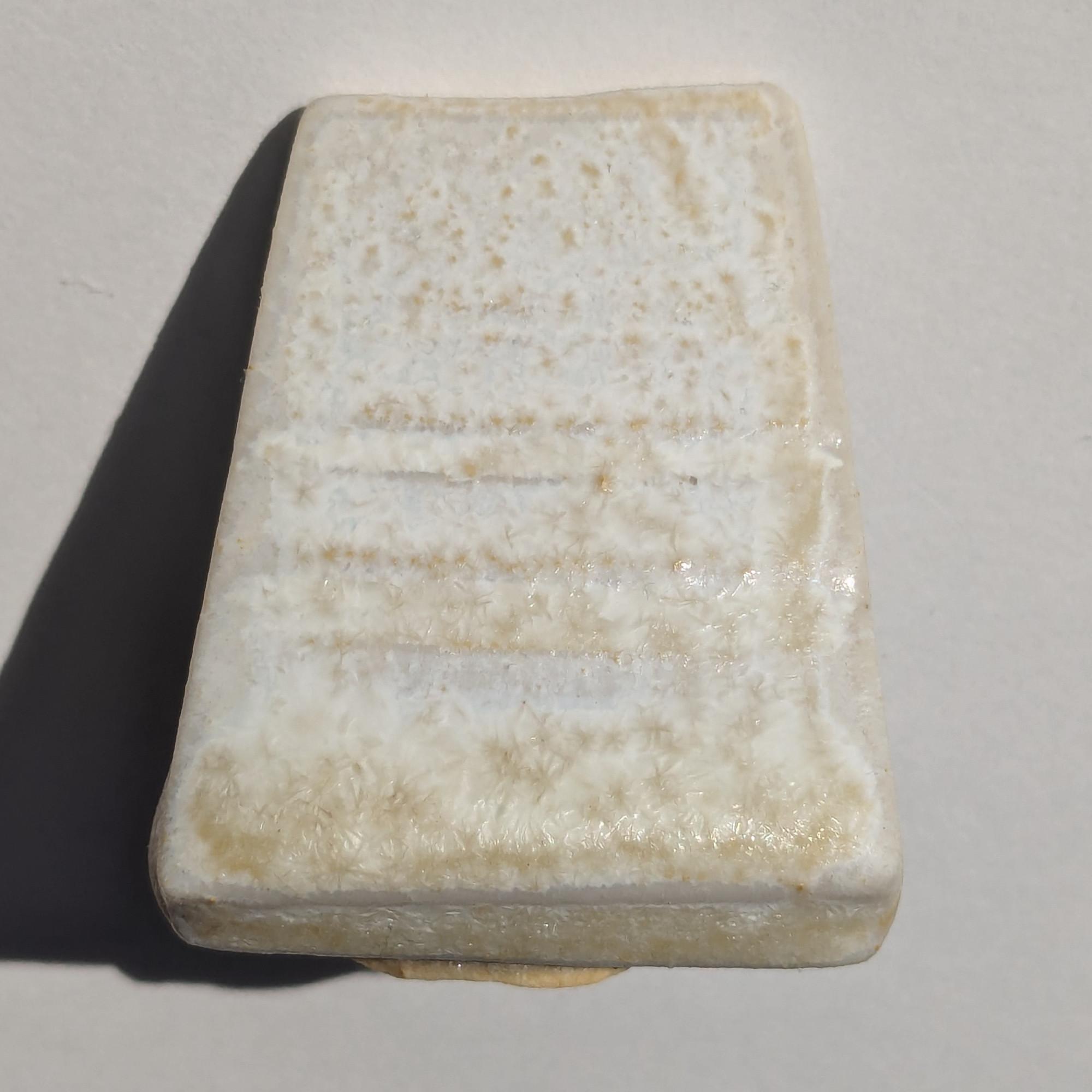

Aggressive melt is on the left and blended with lax melt on the right. There is a smooth transition between the properties of the two end glazes. Surprisingly, the "lax melt" is runnier than "aggressive" melt. It ran more and had larger titanium crystals.

Aggressive melt has fine crystals and is matte. The surface is smooth and pleasant to touch but visually bland. The glaze moves little and doesn't run off the tile. The lax melt is more like the original Galactic Indifference but is over crystallized. The larger crystals mean that it melts more aggressively and is fluid at top temperatures.

This is quite strange as lax melt has less flux and less boron. Could it be because of a eutectic? Or caused by poor measuring of ingredients? If so, the most likely culprit would be lithium carbonate as small differences in weight adds large amounts of flux.

| Ludicrous Melt | Half Titanium | |

|---|---|---|

| Lithium Carbonate | 4 | 4 |

| Whiting | 14 | 14 |

| Ferro Frit 3195 | 57 | 62 |

| Tile 6 Kaolin | 13 | 14 |

| Titanium Dioxide | 12 | 6 |

I made this glaze to push the boron content to the extreme, with over 50% of the recipe as boron frit. I simultaneously tested the amount of titanium dioxide added. Perhaps 12% is too much: maybe I just need a glaze that's highly fluid and contains just a little more titanium than can be dissolved. In which case, I should adjust the titanium content to the fluxing ability of the base recipe.

It's best to think of this glaze in three parts:

| 12 Titanium | 9 Titanium | 6 Titanium |

|---|---|---|

|

|

|

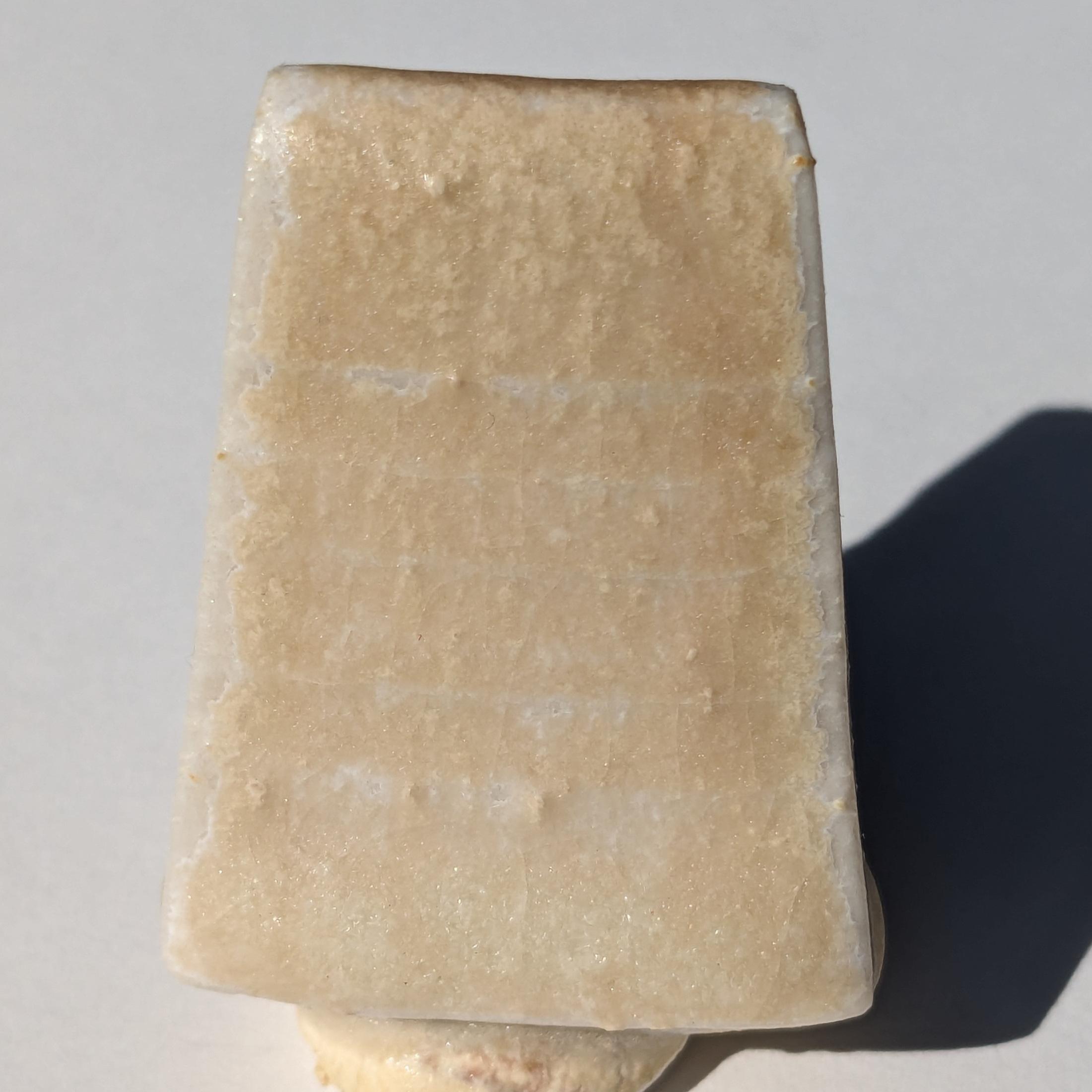

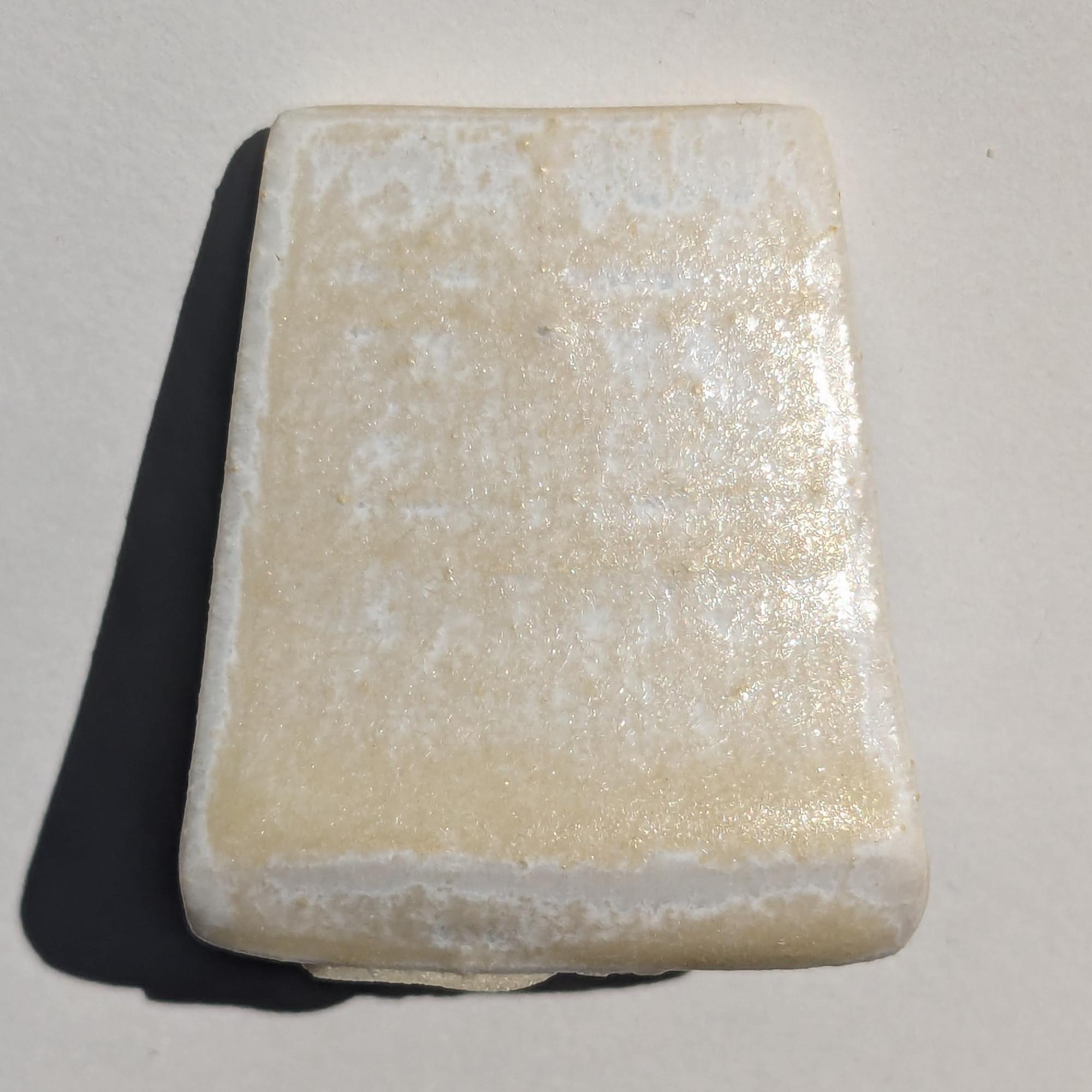

This is strange. The titanium crystallized in clouds. It looks more like melting butter and is quite rough. All three tests ran off the tile, but didn't have the streaking found in the Lax melt recipe.

These glazes are successfully dissolving the titanium; most typical glossy glazes can't dissolve 6% titanium oxide, resulting in variegation. But here the glass is completely transparent.

The crystals feel nasty to touch. I can see that the crystals are long and needle like with a macro lens, unlike the flatter titanium crystals in Galactic Indifference and the Lax melt test. The only conclusion that I can come to is that the boron is negatively affecting the glaze. For the next test, I'll decrease the boron from over 0.4 molar to the more typical 0.15 molar found in cone 6 glazes.

| Material | Percent |

|---|---|

| Lithium Carbonate | 5 |

| Whiting | 29 |

| Nepheline Syenite | 30 |

| Ferro Frit 3134 | 24 |

| EP Kaolin | 12 |

| +14 TiO2 | + 12 TiO2 | +10 TiO2 |

|---|---|---|

|

|

|

This is based on the Lax Melt. EP Kaolin and silica are cut and neph sye and whiting is increased. As always, the Silica-Alumina Ratio is kept around 4.8. The titanium is added in excess of 100% to make adjusting titanium oxide easier.

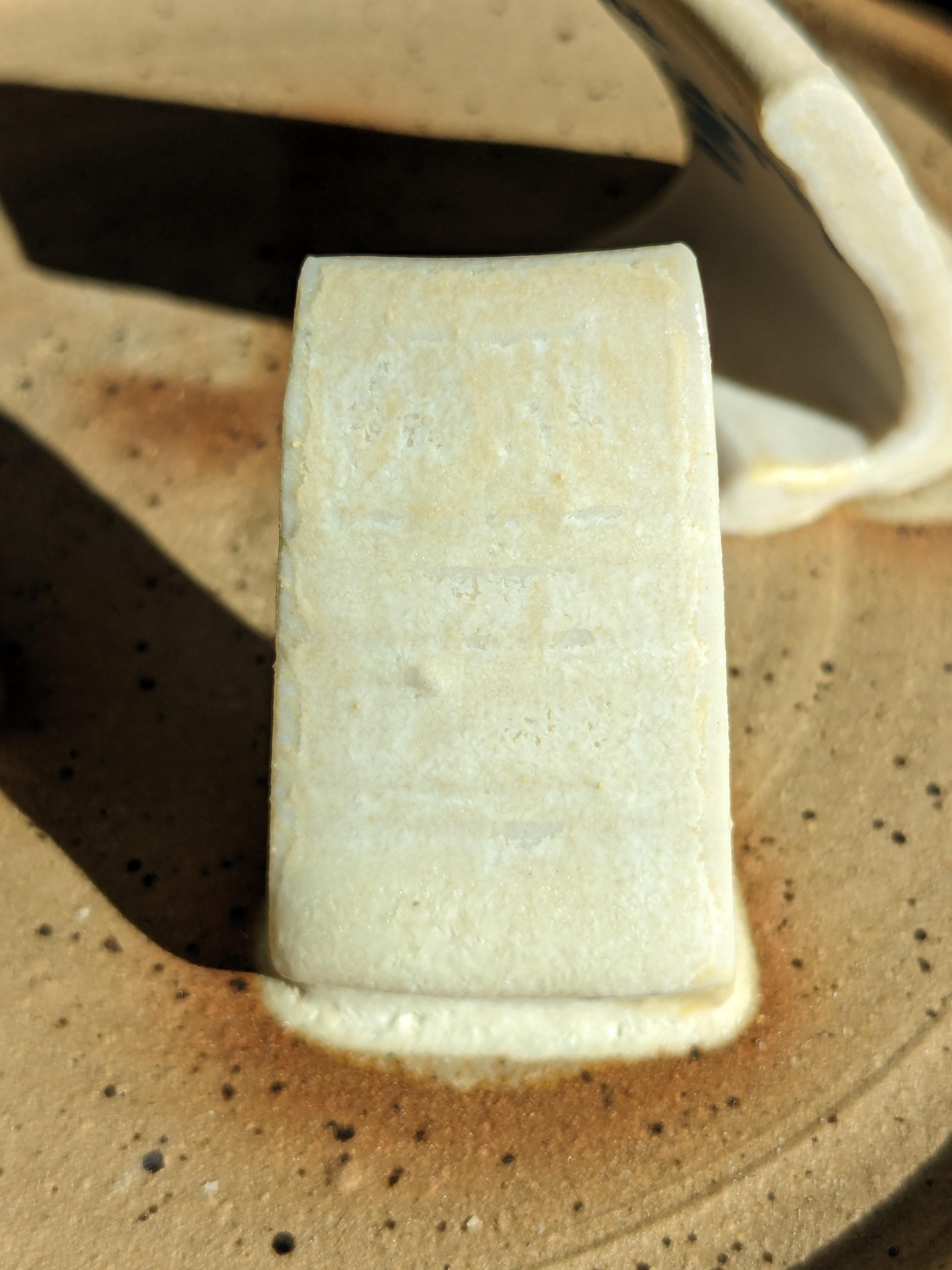

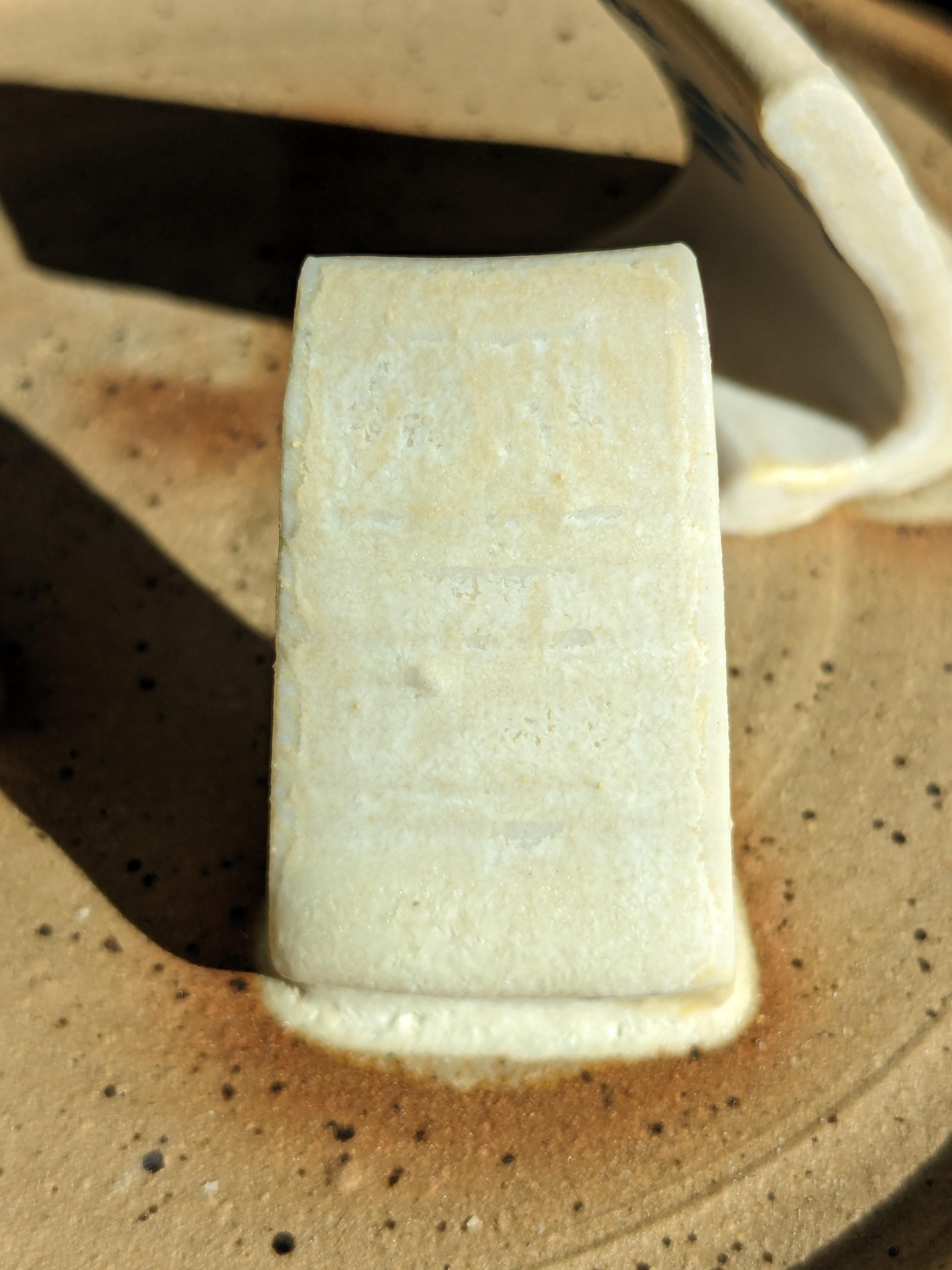

In the electric kiln (which naturally cools faster), the +10 TiO2 test has a more viscous melt and within the glass bead there are large, beautiful titanium crystals. This is what the original Galactic Indifference has. However, the rest of the bead is almost completely transparent. The thicker the melt, the fewer crystals.

At this point, I can make a glaze that has crystals like the original Galactic Indifference, but the rest of the glaze is still clear. It's possible to dissolve 10% titanium in the glaze, but how the glaze crystallizes during cooling is unsatisfactory.

Why isn't the glaze phase separating due to the high titanium content? Why does it go from clear to large crystals with nothing in between? I think the answer is magnesium.

Since MgO stiffens the melt it can be used simply to check glaze fluidity (in a manner similar to alumina) and to prevent devitrification (the tendency to produce crystalline surfaces). When mixed with CaO, it is not as refractory.

The idea is that thickening the glaze by decreasing the flux content decreases the amount of titanium that can be dissolved into the glaze in the first place but magnesium can flux the glaze when melting and then check the over crystallization upon cooling.

Even more evidence to support this fact is that titanium blue glazes (in which titanium causes phase separation) often have a substantial amount of magnesium. Many glazes fall within the 0.2 to 0.4 molar range. Since I can't add talc (as it would increase the silica content), I can only use dolomite - the result is that I can only max out the MgO content at 0.35 molar.

I'll return to the Lax Melt formula because the increased flux test crazed on my porcelain. Lax Melt also has other desirable properties like good suspension due to its 20% kaolin content. The test is simple. I'll perform a line blend and gradually replace all the whiting with dolomite.

| Material | Lax Calcium | Lax Magnesium |

|---|---|---|

| Lithium Carbonate | 4 | 4 |

| Whiting | 20 | |

| Dolomite | 20 | |

| Nepheline Syenite | 18 | 18 |

| Ferro Frit 3134 | 20 | 20 |

| Silica | 6 | 6 |

| EP Kaolin | 20 | 20 |

| Titanium Dioxide | 12 | 12 |

| 0 Dolomite | 5 Dolomite | 10 Dolomite | 15 Dolomite | 20 Dolomite |

|---|---|---|---|---|

|

|

|

|

|

| Material | |||||

|---|---|---|---|---|---|

| Lithium Carbonate | 4 | - | - | - | - |

| Whiting | 15 | - | - | - | - |

| Dolomite | 5 | - | - | - | - |

| Nepheline Syenite | 18 | 19 | 20 | 21 | 22 |

| Ferro Frit 3134 | 20 | - | - | - | - |

| Silica | 6 | - | - | - | - |

| EP Kaolin | 20 | - | - | - | - |

| Titanium Dioxide | 12 | 11 | 10 | 9 | 8 |

Well that didn't work. With the magnesium, decreasing the titanium content didn't increase the crystal size, it just decreased the amount of streaking. Where the glaze pooled, it created rough crystals which are unpleasant to touch.

I'm guessing there isn't enough flux to slowly grow the titanium crystals. The melt needs to be more fluid so only a few nucleation points grow into visible crystals.

The tiles from #More flux, less boron were the only tiles with "low" alumina (0.2 Al2O3). All others had an Al2O3 content of around 0.3. This might be crucial because glazes at 0.25 and lower alumina are fluid enough to create strong visual effects when recrystalizing.

| Material | Low Alumina, Calcium | Low Alumina, Strontium |

|---|---|---|

| Lithium Carbonate | 5 | 5 |

| Nepheline Syenite | 20 | 20 |

| Ferro Frit 3134 | 25 | 25 |

| Whiting | 15 | |

| Strontium Carbonate | 15 | |

| Dolomite | 10 | 10 |

| EP Kaolin | 15 | 15 |

| Titanium Dioxide | 10 | 10 |

I also try swapping out some of the calcium carbonate with strontium carbonate. This makes it similar to the glaze Strontium Crystal Magic (SCM). The difference between my glaze and SCM is that mine has a lower alumina content and enough boron to melt at cone 6.

| 100% Ca | 66% Ca | 33% Ca | 0% Ca |

|---|---|---|---|

|

|

|

|

Where the glaze ran off the tile and pooled, there were some occasional 1mm titanium crystals. On the front of the tile, the glaze was a rough to silky matte (with the strontium being silkier) where thin.

Reducing the alumina content did allow the glaze to dissolve more titanium, but only where the glaze pools. The top of all the test tiles were a dry matte. This make sense from a Silica-Alumina Ratio perspective, but why are pieces fired with the original Galactic Indifference in a soda kiln glossy?

| Material | Low Silica | Medium Silica | High Silica |

|---|---|---|---|

| Minspar | 11 | 10 | 9 |

| Whiting | 9 | 8 | 7 |

| Dolomite | 8 | 7 | 7 |

| Ferro Frit 3134 | 22 | 20 | 18 |

| Ferro Frit 3110 | 22 | 20 | 18 |

| EP Kaolin | 17 | 16 | 14 |

| Silica | 9 | 18 | |

| Titanium Dioxide | 11 | 10 | 9 |

| Low | Med | Hi |

|---|---|---|

|

|

|

The low silica recipe has a Silica-Alumina Ratio of 7.16 and the high version has a ratio of 10.99.

The test tiles were a rough matte no matter what the silica-alumina ratio. The higher silica tiles were smoother, indicating smaller titanium crystals. The increase in silica also gave a bit of a pink blush. This has been observed in the past - titanium can give pinks in conjunction with chrome, similar to the more common tin-chrome pinks.

These have an alumina ratio of 0.24, but don't have the movement and streaking. This means the lithium content is likely crucial for the increased melt.

My hypothesis is that in a Soda Firing, with large amounts of sodium deposited on the glaze surface, soda itself becomes a glass former. This is evident in how even high alumina clay bodies and slips can become glossy in a soda atmosphere. If the sodium were merely acting as a flux on the clay body, wouldn't it make the surface sealed but still matte? After all, clay bodies and slips used in soda firing have silica-alumina ratios far below the 7-8 value needed for a glossy glaze. Indeed, I've seen a mug glazed with Galactic Indifference that was glossy where hit with heavy soda and matte on the other side.

Therefore, to get the same effect outside of a soda atmosphere, the glaze itself needs increased silica to compensate.

In soda firings, the sodium carbonate (soda) is sprayed into the kiln. This additional soda interacts with the clay and glazes, producing the effects distinctive to the firing style.

Conventional wisdom says that this additional soda behaves just like the soda in sodium feldspars, fluxing the glaze. But is that true? Since the application of soda can be directional, we can observe two sides of the same pot.

If the soda simply acted additional flux for glazes, then that means the side of the pot hit with heavy soda should have a lower silica and alumina content. That should translate to runnier glazes. But that doesn't seem to happen.

Clay bodies can have very low silica-alumina ratios. Flashing slips of a known silica-alumina ratio, 4 for example, will go glossy in soda firings. Why? If the soda simply fluxes the clay body to produce a glaze, the low silica content should keep the surface matte.

The only conclusion I can come to is that in soda firings, the additional soda acts as a glass former. The firing builds up a layer of soda glass on top of the existing clay and glaze. Whether that additional glass can be dissolved into the glaze is another issue.

So what glaze goes over? I think any fluid but not runny glossy glaze should work. Titanium crystals should grow at the interface where the solubilities change.

Maybe it is possible to have titanium saturate glazes that don't over crystallize. The very high boron test could dissolve 6% titanium with no problem, something not possible in typical glazes.

Boron is very hard to crystallize

By controlling the alumina and boron levels, it should be possible to control the size of the crystals.

| Material | Low Alumina | MgO | Boron | Boron, MgO |

|---|---|---|---|---|

| Lithium Carbonate | 4 | 4 | 4 | 4 |

| Whiting | 26 | 17 | 24 | 15 |

| Dolomite | 9 | 9 | ||

| Nepheline Syenite | 27 | 27 | 14 | 14 |

| Ferro Frit 3134 | 22 | 22 | 30 | 30 |

| EP Kaolin | 11 | 11 | 18 | 18 |

| Titanium Dioxide | 10 | 10 | 10 | 10 |

| Material | Low Boron |

|---|---|

| Minspar | 10 |

| Ferro Frit 3110 | 25 |

| Ferro Frit 3134 | 15 |

| Whiting | 9 |

| Dolomite | 6 |

| EP Kaolin | 15 |

| Silica | 10 |

| Titanium Dioxide | 10 |

Ok, so I'm not getting the results I want so I think my understanding of the mechanisms are incorrect. After some digging, I found some similar titanium crystal glazes.

These glazes are quite different from Galactic Indifference:

I hypothesize that the mechanism behind Galactic Indifference is actually simpler than I initially believed.

| Material | Low Boron | High Boron |

|---|---|---|

| Nepheline Syenite | 15 | 15 |

| Whiting | 30 | 20 |

| Ferro Frit 3110 | 40 | 15 |

| Ferro Frit 3134 | 35 | |

| EP Kaolin | 15 | 15 |

| Titanium Dioxide | +10 | +10 |

Created . Updated .

Home > Q Science > QD Chemistry > Cosmic Indifference: Galactic Indifference at Cone 6